Maximize uptime and shop efficiency with expert service focused exclusively on general fabrication equipment. Our technicians provide fast, accurate repairs and preventative maintenance to keep your machines operating safely, reliably, and at peak performance. We specialize in hydraulic, mechanical, and electrical systems, along with precision alignment, calibration, and safety inspections for press brakes, shears, plate rolls, ironworkers, band saws, cold saws, and other essential fabrication machinery. Whether you’re addressing an unexpected breakdown or planning proactive maintenance, we deliver dependable service that extends equipment life and minimizes costly downtime.

Keep your CNC machines and machining centers running with precision, reliability, and confidence. Our technicians provide expert repair, troubleshooting, and preventative maintenance to minimize downtime and protect accuracy. We service mechanical, electrical, and control systems, including spindles, drives, servos, ball screws, tool changers, lubrication systems, and CNC controls. From vertical and horizontal machining centers to CNC lathes and multi-axis machines, we deliver precise diagnostics and dependable service that keeps your shop productive and your parts in tolerance.

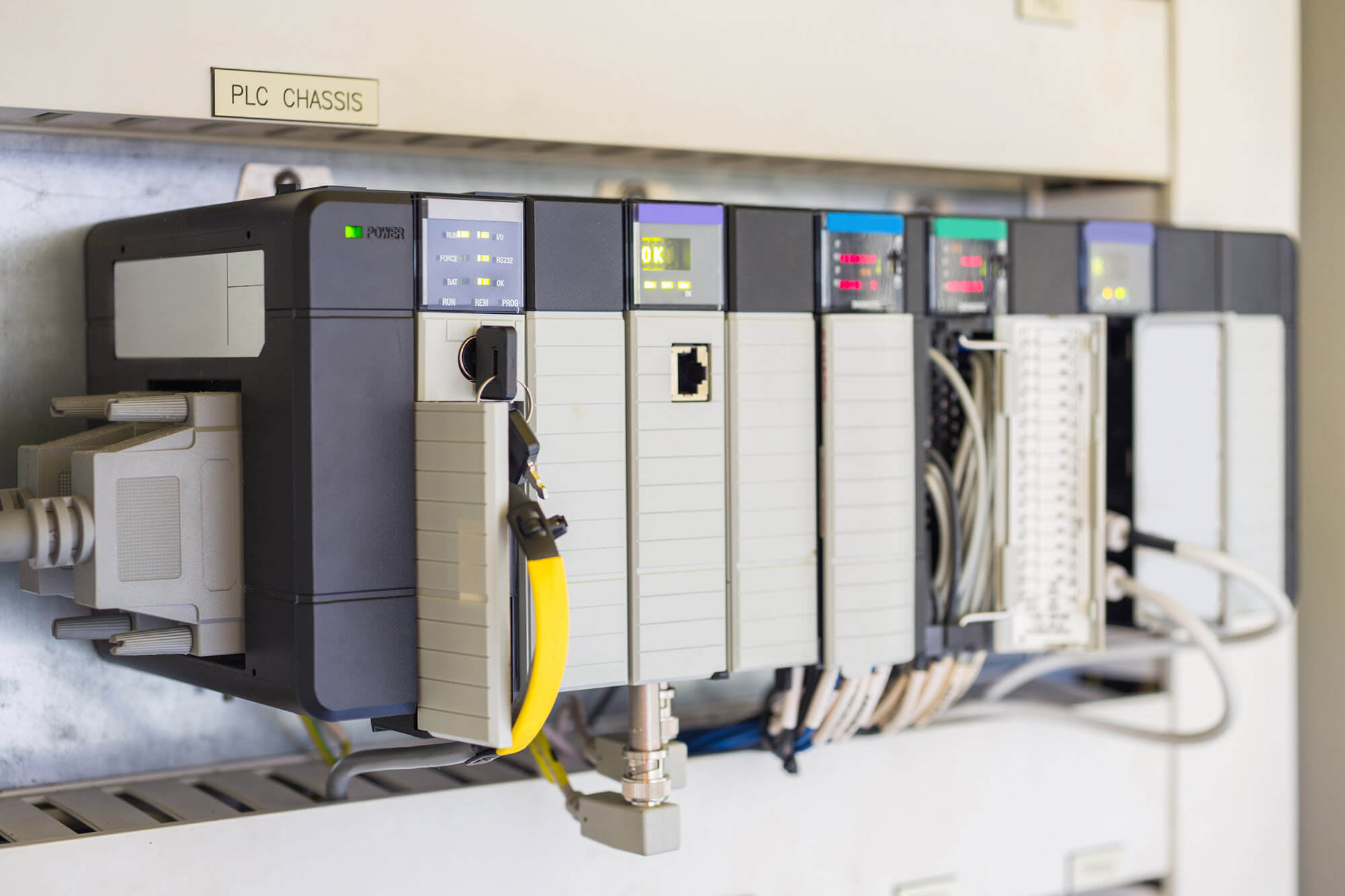

Keep your equipment running efficiently and reliably with expert PLC and industrial automation support. We provide troubleshooting, repair, programming, and preventative maintenance for a wide range of automation systems that control CNC machines, fabrication equipment, and production lines. Our services include PLC diagnostics, HMI and operator interface support, I/O troubleshooting, sensor and safety circuit verification, drive and motor integration, and system upgrades. Whether you’re resolving intermittent faults, improving cycle times, or modernizing outdated controls, we deliver dependable automation solutions that restore stability, improve performance, and reduce unplanned downtime.